About us

Manufacturing site

Back

Automated warehouse

Injection workshop

Soap workshop

Hose workshop

Bottle blowing workshop

Card box printing workshop

Filling workshop

Laboratory

System of liquid workshop

Mould department

Injection workshop

The injection molding and hair planting workshop adopts the GMP dust-free workshop and central feeding system that are rarely used in this industry, adopts fully automated production to ensure product quality.

Central feeding system

Due to the continuous improvement of the technology of the injection molding workshop, the requirements for the quality of the required materials are getting higher and higher, the application of the central feeding system can greatly improve the quality of the products, increase the production efficiency of the workshop, and also improve the environment of the production workshop.

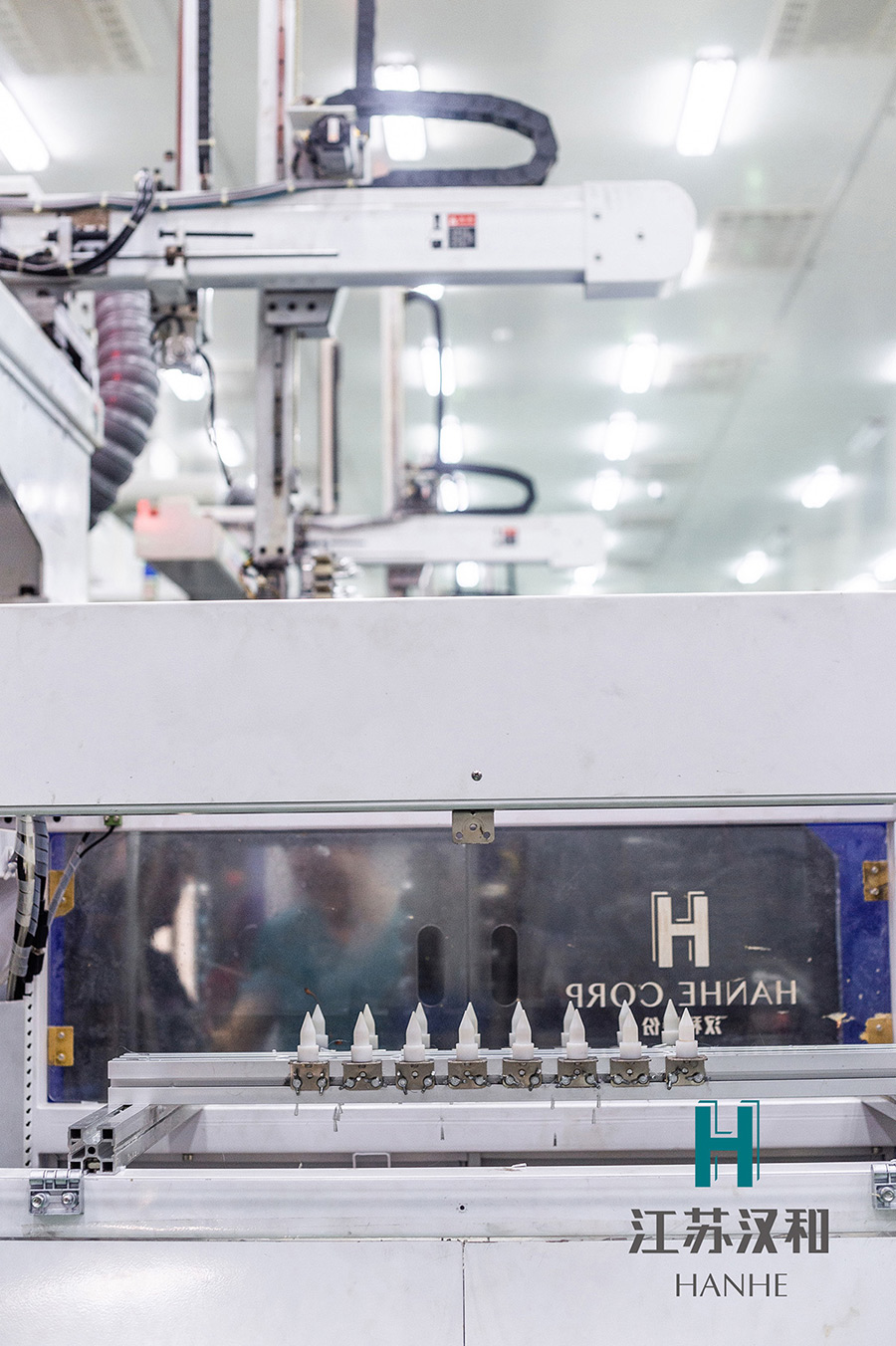

Fully automated production line

The products produced are all automatically grabbed by the robot, packed in boxes, and sent to the follow-up work station, reducing personal operations, and eliminating quality abnormalities and secondary pollution caused by human factors.

Robot palletizing

The company is on the robot automatic palletizing, the AGV car will automatically palletize the products and put the finished products into the warehouse according to the instructions, and the raw materials will be out of the warehouse.

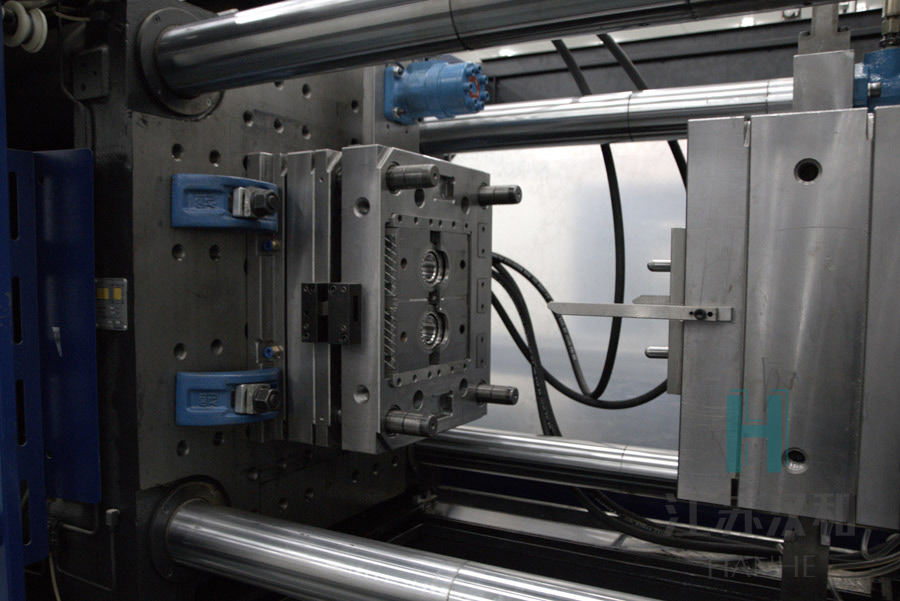

Advanced and complete mold room supporting

In order to ensure the stable operation of the injection molding workshop, the company is equipped with mold room equipment, which can complete the development of new molds and complete mold repair work in time, as well as technical professional mold trial engineers.

Automatic closing machine

The products produced by the injection molding machine are sent to the lid closing machine through the mechanical arm, and the lid is automatically closed by the lid closing machine, which avoids the product scratch problem of the old-style lid closing machine.

Tail trimming machine

The products produced by the injection molding machine are sent to the tail trimmer through the robotic arm, and the tail of the perform produced is cut off by the tail trimmer.

Automatic cutting of toothbrush handle and automatic hair transplanting machine

Toothbrushes are fully automated from injection molding to hair planting, reducing product scratches. The products produced by the fully automatic hair transplanting machine are more stable and cause less waste.

Injection workshop

Injection workshop

Injection workshop

Injection workshop

Injection workshop

Injection workshop