About us

Manufacturing site

Back

Automated warehouse

Injection workshop

Soap workshop

Hose workshop

Bottle blowing workshop

Card box printing workshop

Filling workshop

Laboratory

System of liquid workshop

Mould department

Hose workshop

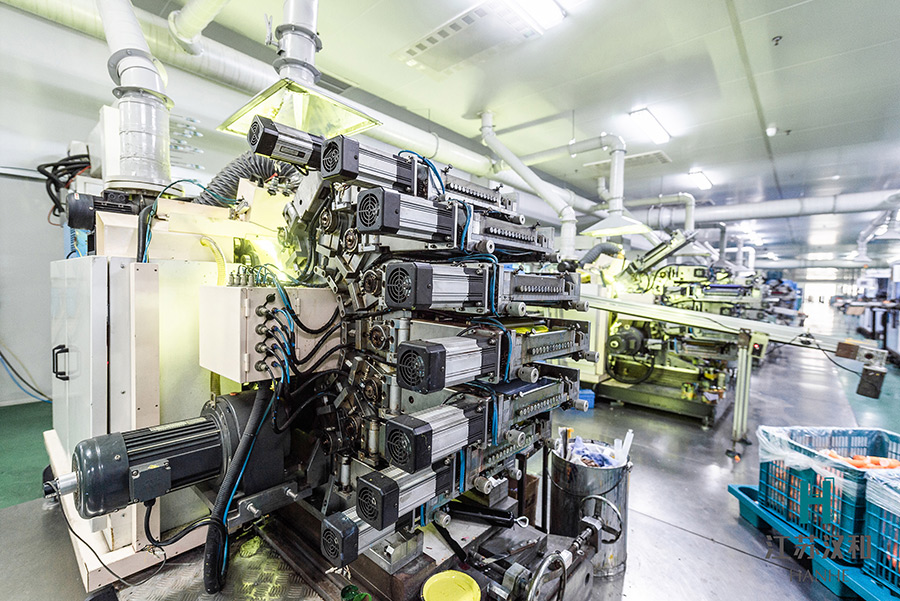

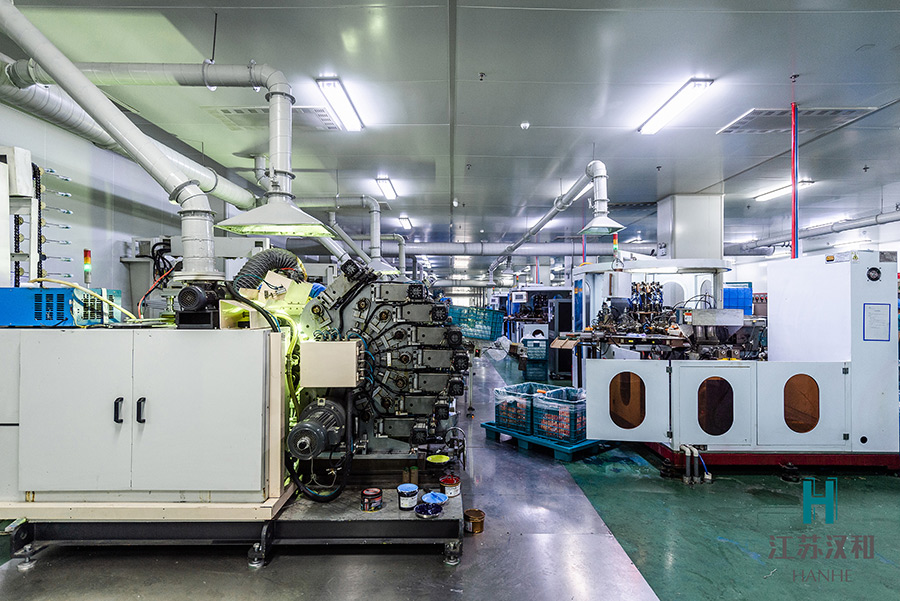

At present, our company has six automatic production lines, which can be formed at one time from drawing, injection, and printing. The biggest advantage: we are also equipped with an 8-color offset printing machine and a fully automatic injection machine. It is currently the most advanced equipment in the same industry. More than 300,000 sticks will be issued.

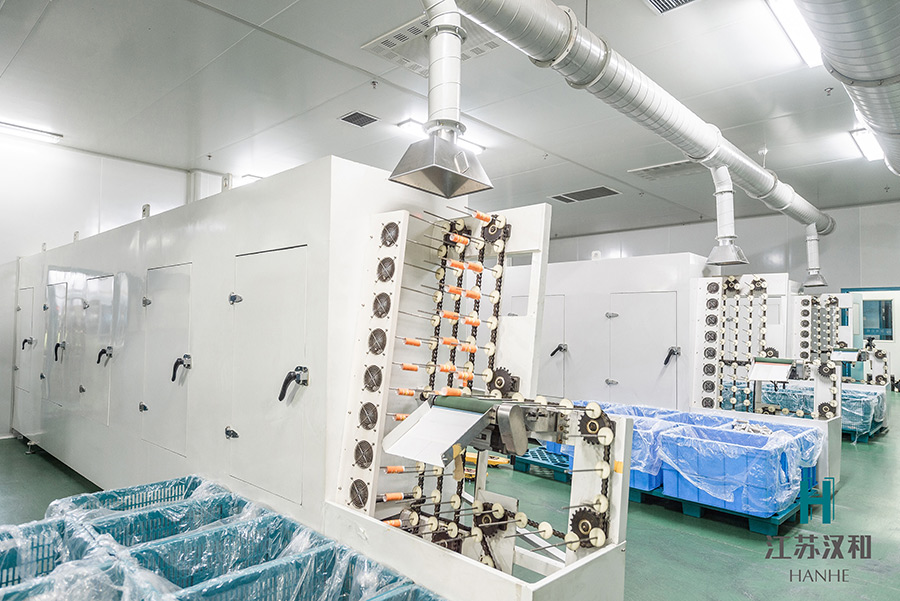

The products in the packaging material workshop are completely inspected manually. After passing the inspection, the pipes are packed into boxes. The goods on the day can be sorted out on the same day and transferred to the warehouse for management.

Our hot stamping machine adopts domestic advanced and fine single station, and the automatic hot stamping machine can hot stamp various colors. Printing color gold can achieve bright color, consistent color and zero error.

The labeling machine is a better equipment in the same industry at present. It can paste various types of labels according to the requirements of customers, which can be completely covered, instead of printing, and can be labeled at fixed points.

The capping machine can be filmed, capped or slapped to form at one time. The tube loading machine is completely developed and produced by our factory.

Fully automatic screen printing machine, can print 3 colors at the same time, overprinting is possible, it can produce about 55 hoses per minute, more than 3000 per hour

In addition, our company's bottle blowing is also at the international level: including double-layer PE and single-layer PE. PVC. PET. bottle blowing machine, bottle UV screen printing machine, card box. paper printing and so on.

1. PE automatic double-layer double-out blow molding machine adopts the domestic advanced level, double-layer double head, and the surface of the bottle body is made of special raw materials, which has a soft touch effect, and the product is more grade and more beautiful.

2. The automatic single-layer double-out PE bottle blowing machine adopts a special bottle body with a liquid level line, which makes the appearance more beautiful and practical.

3. Automatic double-out PVC bottle blowing machine, replacing the semi-automatic bottle blowing machine, with stable performance and better product quality.

4. Automatic PET bottle blowing machine, with high product transparency, good material without seams, more beautiful appearance, and can be used in medicine.

5. The workshop is equipped with a 55-inch touch-control computer display for outputting product information, which is convenient and quick.

6. Four automatic two-color screen printing machines, which can print found, flat, and square bottles. Equipped with the automatic management machine developed by our company, it is convenient and fast, with good product quality and more output.

7. Two-color automatic paper, cassette printer, can print all kinds of paper cassettes, supply the company’s various packaging material product needs, and implement integration.

Hose workshop

Hose workshop

Hose workshop

Hose workshop

Hose workshop

Hose workshop

Hose workshop

Hose workshop

Hose workshop

Hose workshop

Hose workshop

Hose workshop